1. Summary design stage

1.1. After determining the requirements of the system, the system shall be designed according to the following specifications.

1.2. Determine the system cooling method.

1.3. The engineer determines the heat dissipation mode according to customer requirements or preliminary structural layout. Common heat dissipation modes include natural heat dissipation, forced air cooling, and liquid cooling.

1.4. Natural heat dissipation: mainly rely on natural convection to bring heat to the surrounding space, suitable for places with low heating power and low temperature requirements. Advantages: simple structure, no noise, low price.

1.5. Forced air cooling: It is suitable for devices with large heating and power consumption. The forced air cooling has high efficiency, which is usually several times of the natural heat dissipation. Advantages: high efficiency. Disadvantages: easy to produce noise.

1.6. Liquid cooling: Applicable to devices with large heat generation and power consumption, high efficiency. Advantages: high efficiency, low noise or none. Disadvantages: high cost.

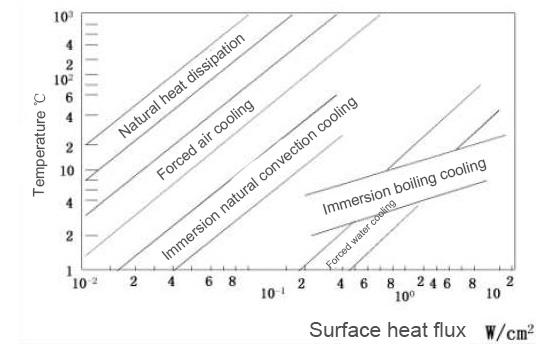

2. According to the calculated heat flux density, the heat dissipation form required by the system can be judged

2.1. Calculation method: Divide the power consumption of the component by the heat sink surface area to obtain the heat flux density.

2.2. The selection principles refer to the following specifications:

2.2.1. For occasions with better ventilation conditions: the heat flux density on the surface of the radiator is less than 0.039W / CM ^ 2, and natural air cooling can be used

2.2.2. For occasions with poor ventilation conditions: the heat flux on the surface of the radiator is less than 0.024W / CM ^ 2, and natural air cooling can be used

2.2.3. For occasions with good ventilation conditions: the heat flux density on the surface of the radiator is greater than 0.039W / CM ^ 2 and less than 0.078W / CM ^ 2, and forced air cooling must be used

2.2.4. For occasions with poor ventilation conditions: the heat flux density on the surface of the radiator is greater than 0.024W / CM ^ 2 and less than 0.078W / CM ^ 2, and forced air cooling must be used

If there is a clear temperature rise limit on the surface temperature, the heat dissipation mode can be selected according to the following table:

2.3. Select reasonable components: components with better heat dissipation performance are preferred.

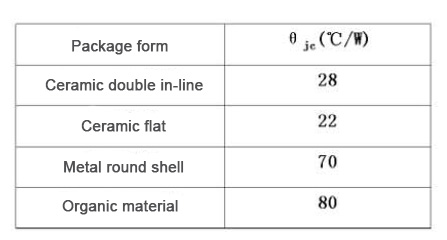

2.3.1. The heat dissipation performance of components in different packaging forms is quite different. The thermal resistance of the components can be obtained from the specifications of the components. Under the conditions allowed by the design, the packaging with smaller thermal resistance is preferred.

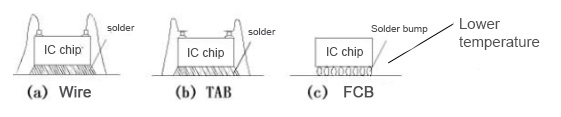

(1)Chip bonding method

(2) Thermal resistance reference value from junction to case GJB / Z 299B

2.4. Derating components

Under the premise of balancing costs, the power of components can be reduced, thereby increasing the parameter margin of components and reducing heat generation. The general derating factor is between 0.5 and 0.8.

2.5. Scientific installation of components

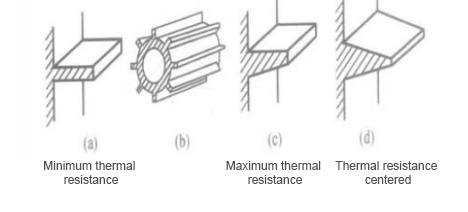

A) Resistance

Large size horizontal installation, reserve enough deformation space, reserve 0.13-0.16mm minimum thermal resistance under the patch

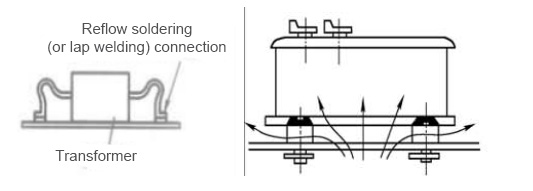

B) Transformer

Leave holes underneath, the surface becomes black

2.6. Reasonable choice of radiator

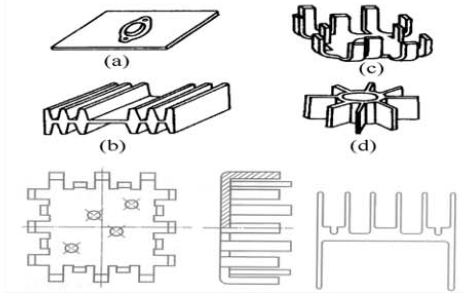

There are many types of radiators, and a reasonable choice of radiators can improve the efficiency of heat dissipation and reduce costs.

2.6.1. Commonly used radiators

Commonly used radiators are aluminum extrusion, sheet metal stamping, heat pipes, ceramic radiators, etc.

Average price level: ceramic radiator <sheet metal stamping <aluminum extrusion type <heat pipe

Heat dissipation capacity: sheet metal stamping> aluminum extrusion> heat pipe

Ceramic radiators are generally used for radiant heat dissipation

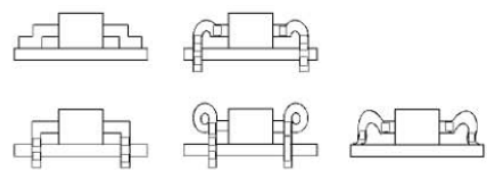

2.6.2. Commonly used rib shape design

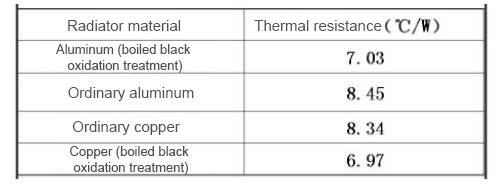

2.7. Effect of blackened surface on heat dissipation

The blackness of the surface of the object has a significant effect on the radiation and heat dissipation, and the following principles are followed when designing:

2.7.1. In the case of higher than 50 degrees, increasing the blackness can effectively increase the radiation heat dissipation and improve the heat dissipation efficiency;

2.7.2. For the case of forced convection, the radiation effect is weak, and the effect of blackness can be ignored;

2.7.3. For the case where the surface temperature is below 50 degrees, the radiation heat dissipation effect is weak, and the influence of blackness can be ignored;

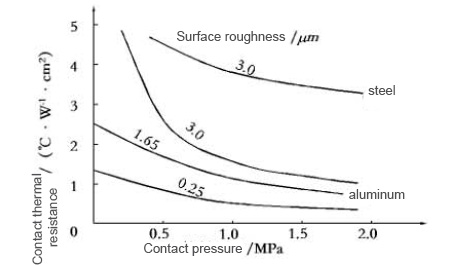

2.8. Reduce contact thermal resistance

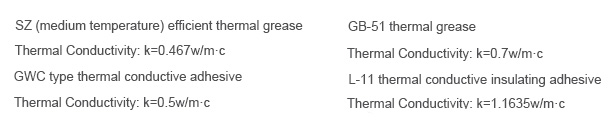

2.8.1. Applying a thin layer of thermal conductive adhesive can effectively reduce the contact thermal resistance and increase the heat dissipation speed

2.8.2. Increasing contact pressure (≥200N / CM²) can also reduce contact thermal resistance

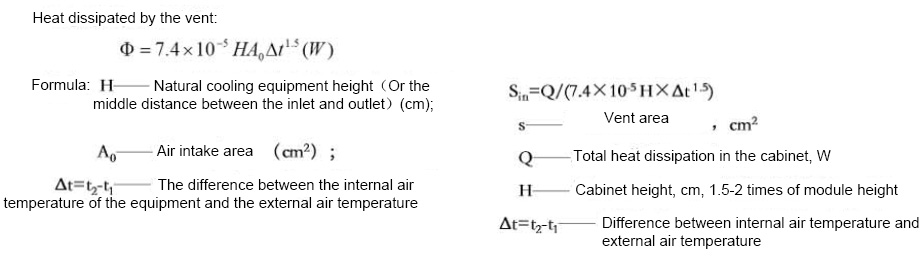

2.9. Reasonable design of heat dissipation holes

The calculation of the vent area can be calculated according to the following formula

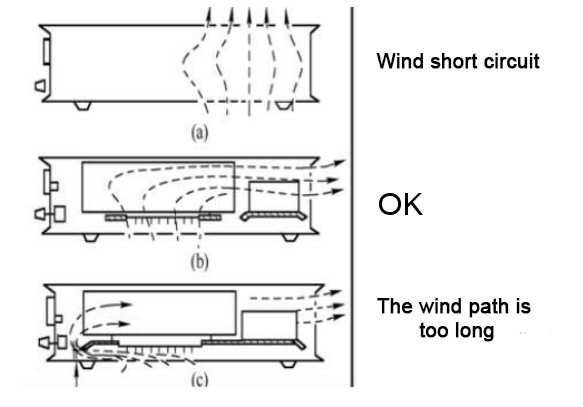

The location of the heat dissipation holes should be reasonable, and the control air path should follow the following principles:

2.10. Reasonable selection of fan and structure

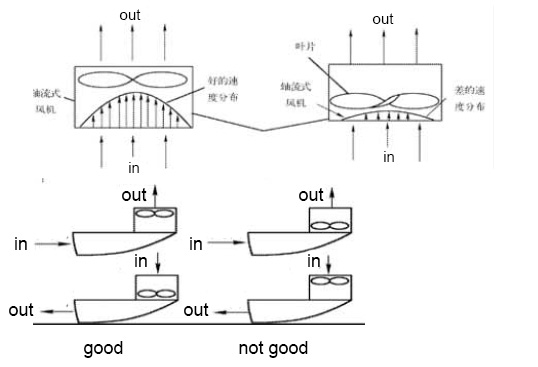

There are two types of commonly used fans: axial fans and blower fans. Axial fans are often used. Axial fan installation should use smokestack effect as much as possible.

2.11. Reasonable design of air duct

The design of the air duct directly affects the air flow inside the product, and a reasonable air duct design can improve the heat dissipation efficiency.

2.11.1. The air duct must be sealed on the side, and the air duct flows through the main heat sources;

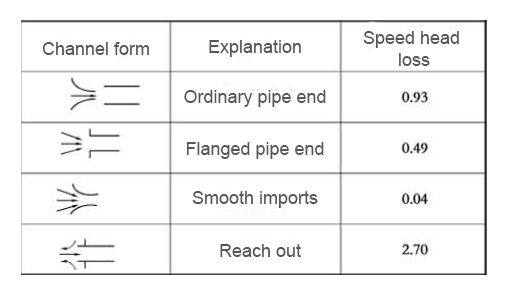

2.11.2. The imported shapes refer to the following design parameters:

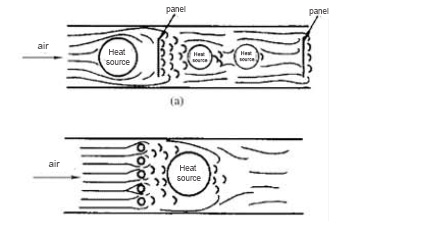

2.11.3. Adding turbulators can improve the efficiency of air ducts:

Consider the above design specifications and determine the general heat dissipation layout and structure in conjunction with product structure requirements.